Magnetics

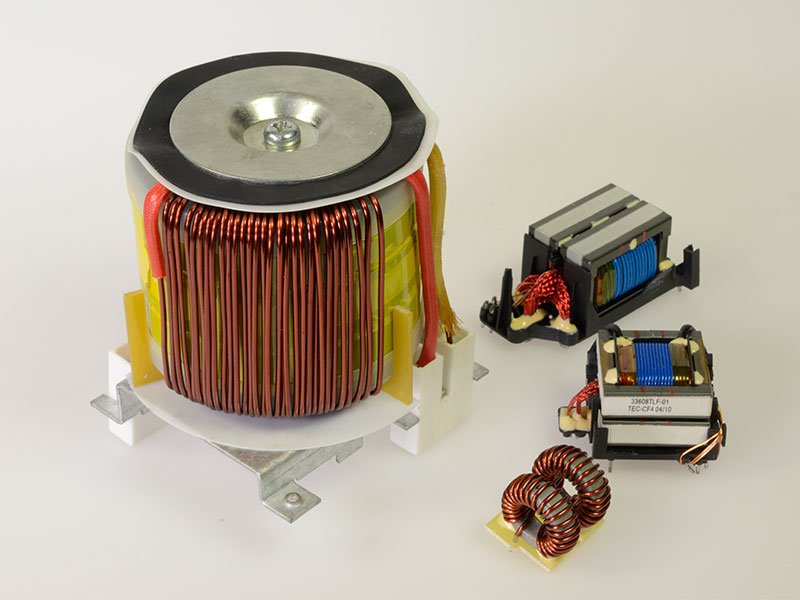

In-house design and manufacture of wound components

Trio Engineering is celebrating 40 years of being a competent partner and manufacture of highly innovative and quality wire wound magnetic solutions.

Magnetics are usually broken down into four main categories; low frequency, high frequency, isolated and non-isolated. Utilizing the application specific requirements, custom designs from our customers to meet their specific electrical and physical parameters and our unique capabilities in both design and manufacturing we have achieved many long-term partnerships.

Although machines are used to wind the wire onto a bobbin, a considerable amount of manual assembly is still required to add insulating tape between the windings, remove the wire coating for terminations, bend and shape leads, and to add insulating sleeves to flying leads. Our highly qualified and experienced staff can meet the challenges in this area.

Our wire would magnetics include high quality custom transformers, inductors, chokes and coils that can be used for panel, rack and PCB requirements.

Typical Products that we make using the magnetics from the four categories are:

Low Frequency Magnetics

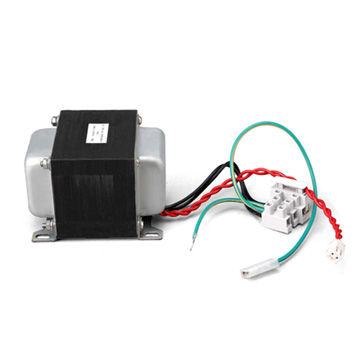

Considered to be 50 or 500Hz and connected to the 220 to 240V AC single phase mains input in Europe, Asia and Africa, or 115V AC mains input in the Americas.

- Line Filters

- Motor Drives

- Uninterruptable Power Supplies (UPS)

- Pump Systems

- Conveyor systems

- HVAC equipment

- Linear power supplies

- Electricity meters

High Frequency Magnetics

Introduced with high efficiency switched mode power supplies (SMPS).

- Switching and regulating LEDs

- Medical Systems

- EV Chargers

Non-Isolated Magnetics

Inductors

- Filters

- transformers to ‘step-up’ or ‘step-down’ AC voltages.

Isolated Magnetics

Where human contact with electricity is possible isolated transformers become necessary to avoid electric shocks. The transformer windings have one or more layers of insulation added, which usually consists of the plastic bobbin and insulation tape. One of the most extreme applications for our isolated magnetic products in the field of medical electronics, where the barrier uses triple insulation and/or a spacing of several millimetres.